For Iron and Steel Industry many parts of Machinery need intensive water cooling, such as shell and roof of EAF, LF, Ductworks of Dedusting System, etc..

Life time of these water-cooled parts is in strict relation with the water cooling method and efficiency. Life time of these water-cooled parts may be extended using HCW - Hot Cooling Water Technology. Hot cooling water reduce the chemical and thermal stress of the water-cooled elements. Hot water temperature reduce the risks of acid condensations, which are usually promoting various type of corrosions process. Higher and more stable values of cooling water temperature, reduce the thermal stress induced by the natural deformation of steel materials.

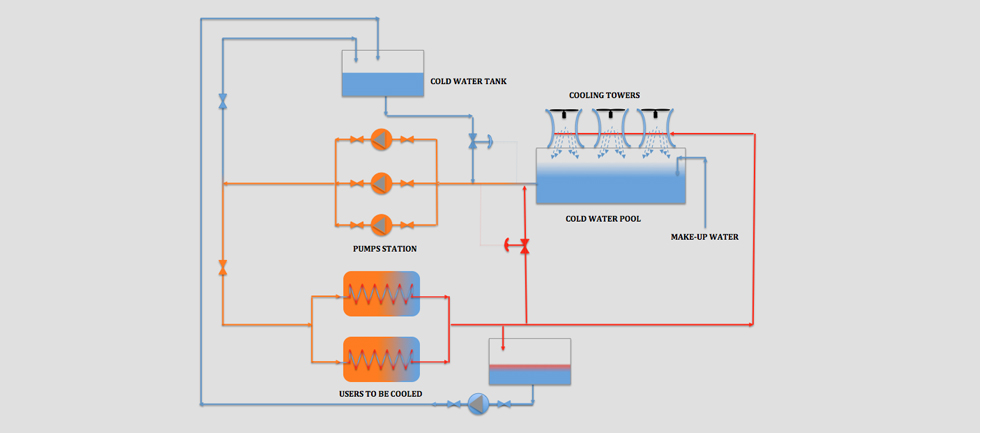

During the steel production process the heat rejected by the process may change significantly. Conventional Water Cooling system can not adapt their working and cooling effect so rapidly. With our technology in case the heat rejected is reduced, cooling water can bypass automatically the cooling towers totally or partially, thanks to an automatic regulation control system. As well in the event of peak of heat rejected, some additional cooling water can be fed instantaneously by the cold water tank. Control regulation system is able to stabilize significantly the temperature of inlet cooling water supplied to water cooled parts, improving the respective life time.

Hot Cooling Water Technology provide the following major advantages, compared to a conventional Cooling Water system: